The metal processing challenges system integrators

Device integration

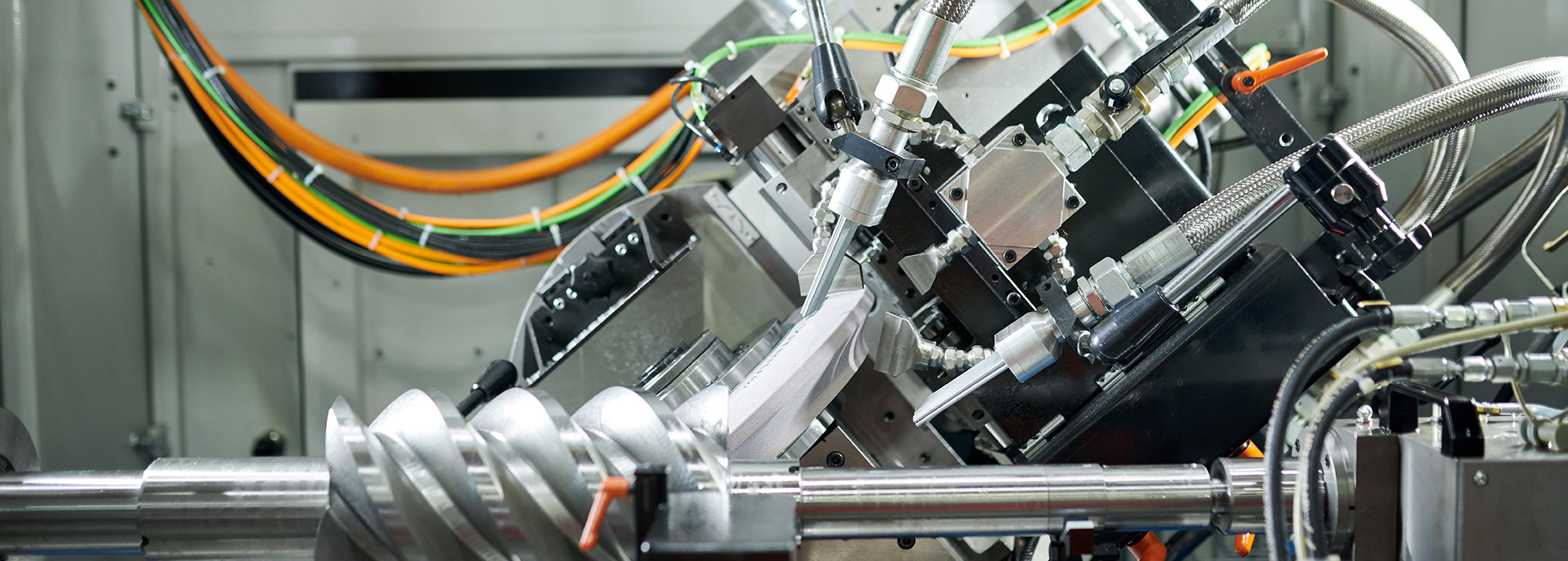

To implement robotic grinding, system integrators must choose the right endeffectors, robots, force control devices, programming software and abrasive materials.

System Integrators have to spend unforeseen resources to develop ad-hoc adaptations for both hardware and software that comes from different suppliers.

Process optimization

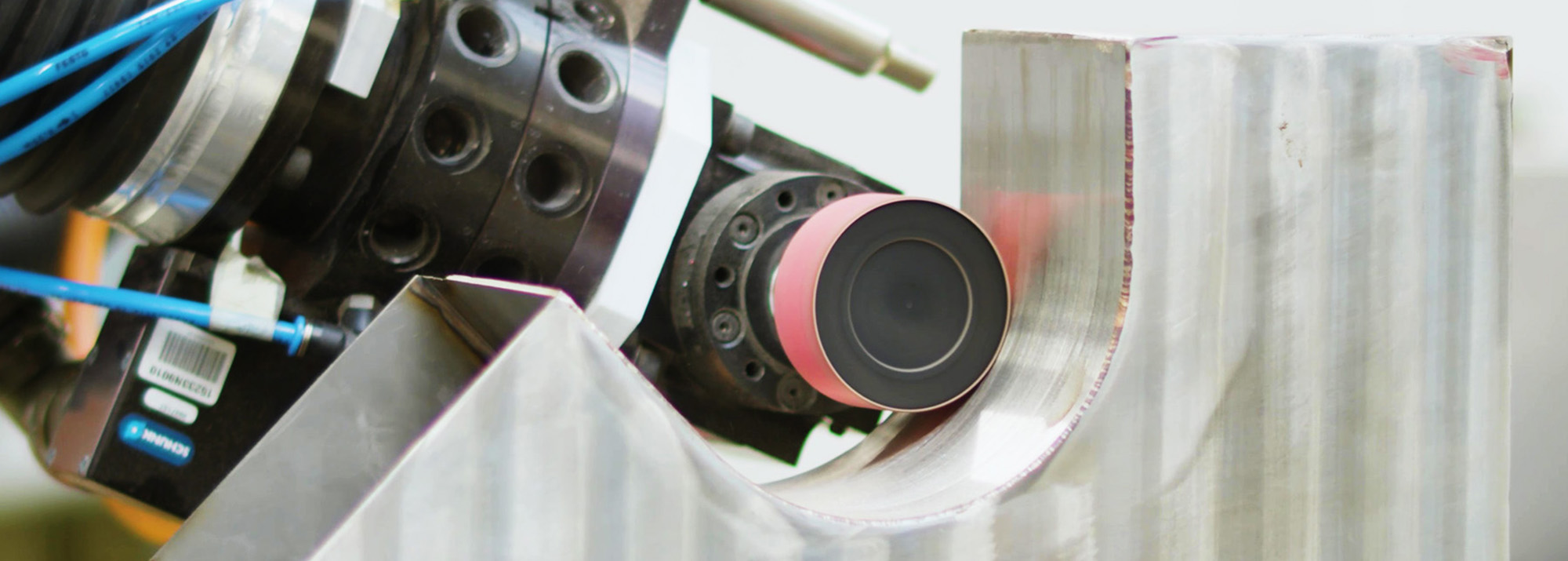

Abrasive process knowledge is the single element that most impact final surface quality.

Usually this is not a system integrator’s core competence and represents high risk to deliver a successful project.