Deploy skilled

labour more effectively

Increase productivity

Reduce production

costs

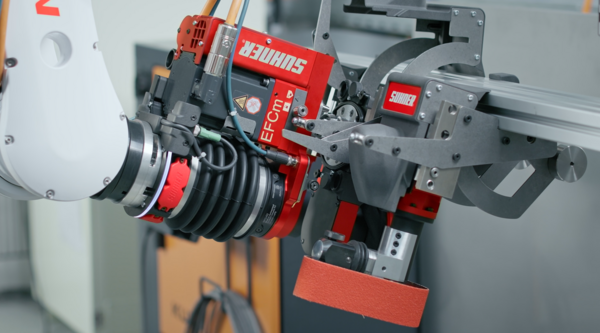

EFCm-02 high-performance end effector for robot-assisted metal processing

Automate your grinding processes with the SUHNER Electric Force Compliance System EFCm-02 and benefit from maximum advantages in the production process. The modular system of end-of-arm-tooling (eoat) for grinding with robots enables precise and consistent grinding quality. The result: higher productivity and lower reject rates.

Advantages of metal processing with modular and robotised end effector from SUHNER

The EFCm-02 end effector is attached to the end of the robot arm and interacts directly with the workpiece. It performs tasks such as cutting, grinding and polishing (material removal processes). This end effector has a modular design and makes a decisive contribution to the versatility and efficiency of industrial robots. The SUHNER Electric Force Compliance System sets new standards. The all-electric operation enables constant monitoring of force and acceleration during surface finishing by measuring at high frequency. The concrete advantages in metal processing:

- Reduction in production costs

- Reduced workload and less risk of injury for employees

- Greater flexibility when processing complex work elements

All-electric operation enables constant force control during surface finishing by measuring at high frequency.

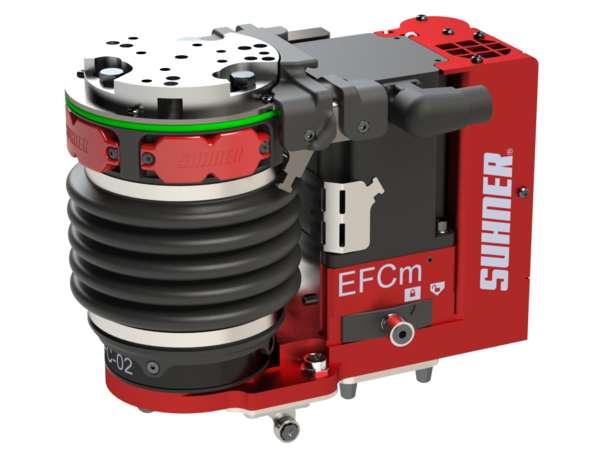

The SUHNER Electric Force Compliance System modular EFCm-02

The EFCm-02 system offers a number of advantages:

- Modular system for changing tools/heads in the existing robot cell

- Variety of applications

- Consistent and high-precision grinding quality for higher productivity and fewer rejects

- Automated processes

- High flexibility when processing complex parts

- 40 % smaller than standard market solutions

- Sophisticated concept for greater cost efficiency

- Complete package that is easy to install

These features allow the EFCm-02 system to maximise flexibility, especially with the ability to efficiently process hard-to-reach areas.

Areas of application

The EFCm-02 system offers a wide range of applications thanks to its modular design. Specific fields of application for the EFCm-02 high-performance end effector in robot-assisted metal grinding include:

- Food and pharmaceutical industry: Stainless steel components for the pharmaceutical and food industries. The focus here is on removing weld seams on stainless steel parts with the highest precision.

- Metal equipment: Stainless steel modules for kitchens, catering, sinks, hospitals, public facilities. For high hygiene standards, the highest quality is achieved when removing weld seams.

- Automotive industry: In automotive production, the end effector is used to process metal in body parts, engine components and chassis parts. Whether frame parts or extruded parts: The precise grinding technology improves the surface quality and prepares the parts for painting processes.

- Wagon construction and maintenance: Wagon/vehicle construction/cab construction/maintenance of rails and points to increase the service life and performance of the machines.

- Metal constructions (all materials): Metalwork on all materials; forging, stairs and railings, frame parts, apparatus construction, etc. for increased operational reliability.

- Aircraft construction: manufacture and maintenance of: Engines, cabins, landing gear, etc. Here the end effectors are used to machine metal in turbine blades, aircraft structures and other critical components. The ability to machine complex geometries with high precision is particularly important in this industry.

- Plant and mechanical engineering: For manufacturers of plant and machinery, such as shipbuilding and shipyards, the end effectors offer precision quality.

These areas of application demonstrate the versatility and wide range of uses of the EFC-02 and EFCm-02 end effectors in the industrial environment.

Flexibility and adaptability: the advantages of modularity

The modular design enables flexible adaptation to different sanding processes and thus guarantees optimum results for different workpieces and requirements.

- Easy replacement and expansion: Components of the sanding system can be easily replaced or expanded to meet specific needs and challenges.

- Fast response to changes: Adaptation to changing production requirements is quick and straightforward.

- Efficient use of resources: The available resources are optimally utilised as the robot cell does not need to be replaced.

- Outstanding quality: Another plus point for the excellent device from the SUHNER Electric Force Compliance System series.

Your benefit: The productivity and quality of the sanding processes are significantly increased.

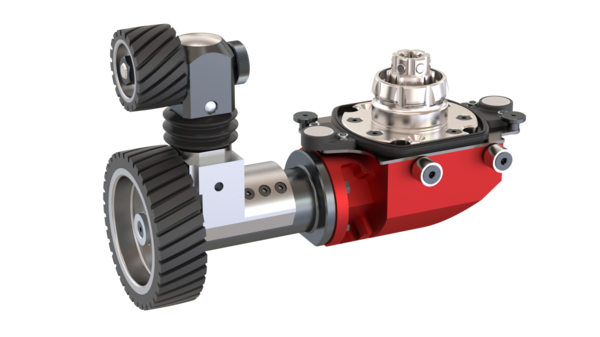

The grinding processes

When it comes to surface finishing, using the right abrasive is the key to an efficient and high-quality process. Suhner's end effectors make it possible to optimise a wide range of processes. Thanks to the large selection of modular heads and the automatic belt and disc changers, unmanned processes are possible without any problems:

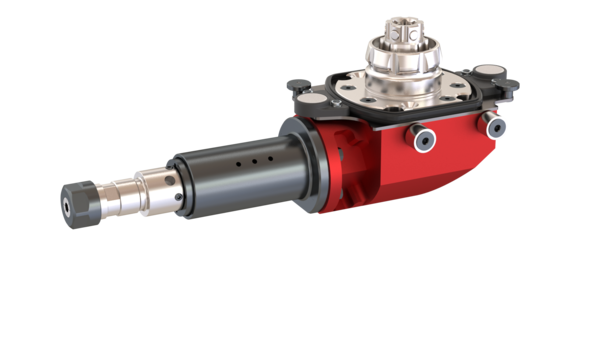

- Angle grinders: versatile for cutting, stock removal, grinding and polishing.

- Belt grinder: high removal rate for large areas and special surface finishing

- Straight grinder: A variety of grinding discs and grinding mops can be used for coarse work through to high gloss.

- Orbital sander: For surface preparation before painting and paint polishing.

Access to small areas is many times more efficient than with hand-held tools. The advantages at a glance:

- Efficiency: Fast and precise work.

- Flexibility: Adaptable to different workpieces and requirements.

- Automation: Reduces labour costs and errors.

- Quality: Consistent results, even in hard-to-reach areas.

Angle grinder head

Orbital sander head

Straight grinding head

(not yet available)

Belt grinding head

(not yet available)

The mission of SUHNER

As experts in surface finishing with hand tools, we develop excellent robotic rinding solutions, end effectors, abrasives, process expertise and accessories that can be easily implemented by any robot integrator. Our solutions are suitable for all industries that want to increase their production efficiency, especially for small production volumes.

Thanks to cost-efficient solutions and short set-up times, you as a company can benefit quickly and effectively from our innovative technologies.

SUHNER not only offers individual products, but also well thought-out and innovative complete solutions that are continuously developed and based on comprehensive expertise. What also sets us apart:

- Many years of experience: we have been developing end effectors and metalworking systems in collaboration with various system integrators for many years.

- Quality promise and special service: Our support offers technical assistance and insight into industry trends and innovations. That's why we offer an end effector rental service. This allows you to easily and risk-free test how the equipment can improve your processes.

Testing-Service

Test our products directly on your workpieces and see their performance for yourself. We support you in the transition from manual grinding to robotic grinding, even in the production of small batches in the metal industry.

Our vision is to maximise production efficiency through the use of robotic grinding and thus promote a more sustainable future. Also discover SUHNER Robotic Grinding, SUHNER Roboter-Applications and Robotic-News to make sure you don't miss out on any exciting insights.

Benefit from our experience and our customised solutions that optimise your production processes and increase the quality of your products!

Get in touch with us!

Your contact for the automation of your grinding processes

SUHNER Schweiz AG

Industriestrasse 10

5242 Lupfig

Switzerland

Tel: +41 56 464 28 28

E-Mail: robotics@suhner.com