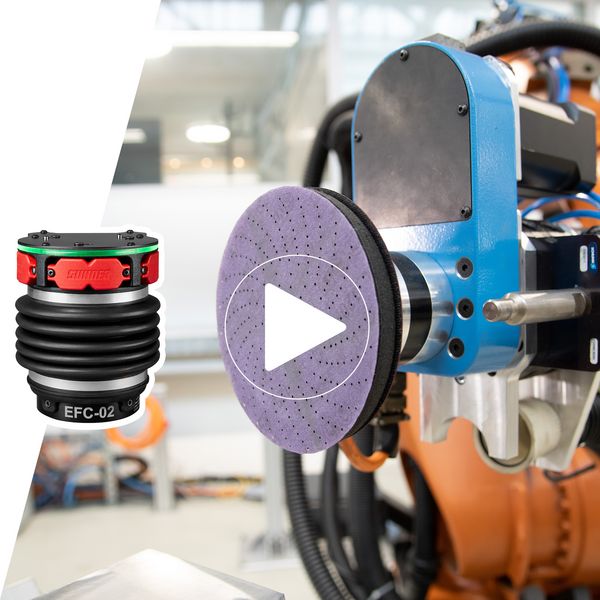

The SUHNER Electric Force Compliance (EFC-02) system is the solution to automate your grinding processes

End-of-arm-tooling (eoat) for robotic grinding

Reduce production costs and increase productivity with the SUHNER EFC-02 Active Electric Force Compliance System. The end-of-arm-tooling connects the grinding machine to the robotic arm. The fully-electric operation allows constant monitoring of force and acceleration during surface finishing through high frequency measurements.

SUHNER Robotic Grinding supports your transformation

Our fully-electric technology is ideal for small and big batch production. The compliance function simplifies robot programming and ensures consistent surface quality. With SUHNER Abrasive's process know-how, you increase the efficiency of your production. Supplemented by suitable grinding machines and abrasives, you achieve consistently high quality. Make the switch from manual work to robotics.

Transforming manual grinding, polishing, sanding and deburring operations into robotics have key benefits for metal processing

Empower Your

Skilled Labor

Increase

Productivity

Lower

Production

Costs

Simple Device

Integration

Abrasive Process

Know-how

Production

Flexibility

In metalworking companies, the shortage of skilled workers and increasing demands for sustainability is an important issue. Work performed by people has the greatest impact on costs and productivity.

Productivity

Almost any welded structures, requires post processing to be removed or blended. This could be up to two thirds of the production time and could be affected by absenteeism, operator injuries and operator wearing.

This currently represents a bottle neck towards a more efficient and more sustainable productions.

Production cost

Manufacturing metal structures requires huge number of man-hours, to remove welds, burrs and obtain a high-quality product.

Especially in sectors as medical, pharmaceutical and food, where the surface quality is critical to ensures hygiene regulations, the manual post processing could cost up to half of the production costs.

Skilled Labor

Metal processing quality strongly depends on the manual skills of the person doing it. Less and less people want to do this hard and dangerous job and manufacturers struggle in finding labor.

This is well-in-line with the Megatrend of Sustainability, that not only means taking care of the environmental impact, but it is also to ensure a good life quality of everyone.

Advantages of SUHNER’s fully-electric end effector for grinding, polishing, sanding and deburring

Exact contact force with the surface is the single most important factor in robotic grinding, sanding and deburring processes – and one of the biggest challenges. This is critical throughout the process regardless of variations in surface shape and orientation.

EFC-02 Active Compliance End Effector is fully electric. This enables constant monitoring of force and acceleration during machining through high frequency measurements. The control algorithm dynamically and automatically adjusts the force to the grinding process. The result is consistently high surface quality.

Enables automation

of complex parts

Adapted to small and

big lot productions

Fully electric and

easy to integrate

The result is consistently

high surface quality

Robotic grinding with SUHNER EFC-02

Precise force control

in all orientations

Access to tight areas access

thanks to compact design

Visual operator

feedback with LED

Maximized up-time with

data-driven maintenance

notifications

Stand-alone operation with

48V power supply and

ModBus or web interface

A complete range of end effectors and abrasive changers to automate your process

Angle grinders, orbital sander, angle polisher, roller units and straight grinders can be used with SUHNER’s end-of-arm-tooling. In addition, automatic abrasive changers can be used.

Contact us!

Your contact for the automation of your grinding processes

SUHNER Schweiz AG

Industriestrasse 10

5242 Lupfig

Switzerland

Tel: +41 56 464 28 28

E-Mail: robotics@suhner.com